Lime juice clear cordial

Practical Action

length and rotate inwards powered either by hand or electric motor. One roller is of a slightly

larger diameter than the other which provides a shearing action as the fruit passes through. The

gap between the rollers can be adjusted and maintained by heavy springs.

The production of lime cordial requires the juice to be clarified in order to produce a crystal

clear final product. Crude juice contains fruit debris and a cloud caused by fruit pectins. The

raw juice squeezed from the limes needs to be 'racked' - or allowed to clear thus allowing the

crude solid pulp to settle. Calcium carbonate is added at this stage. This reacts with the fruit

pectins and produces calcium pectate which settles with fruit solids.

In order to preserve the juice during this settling time, sodium metabisulphite must be added at

the rate of 3g/litre to provide a sulphur dioxide level of 1000ppm (parts per million). After

dilution with sugar syrup, described below, this level will drop to meet legal limits.

Racking can be carried out in a large wood or food grade plastic tank with a lid and a drain-valve

above the level of the solids that have settled. Racking time will vary, but three to five weeks is

normal. It should be noted that provided SO2 levels are maintained, the juice can be stored in

racking tanks for some considerable time, thus allowing a production unit to concentrate on

juice extraction during the height of the lime season.

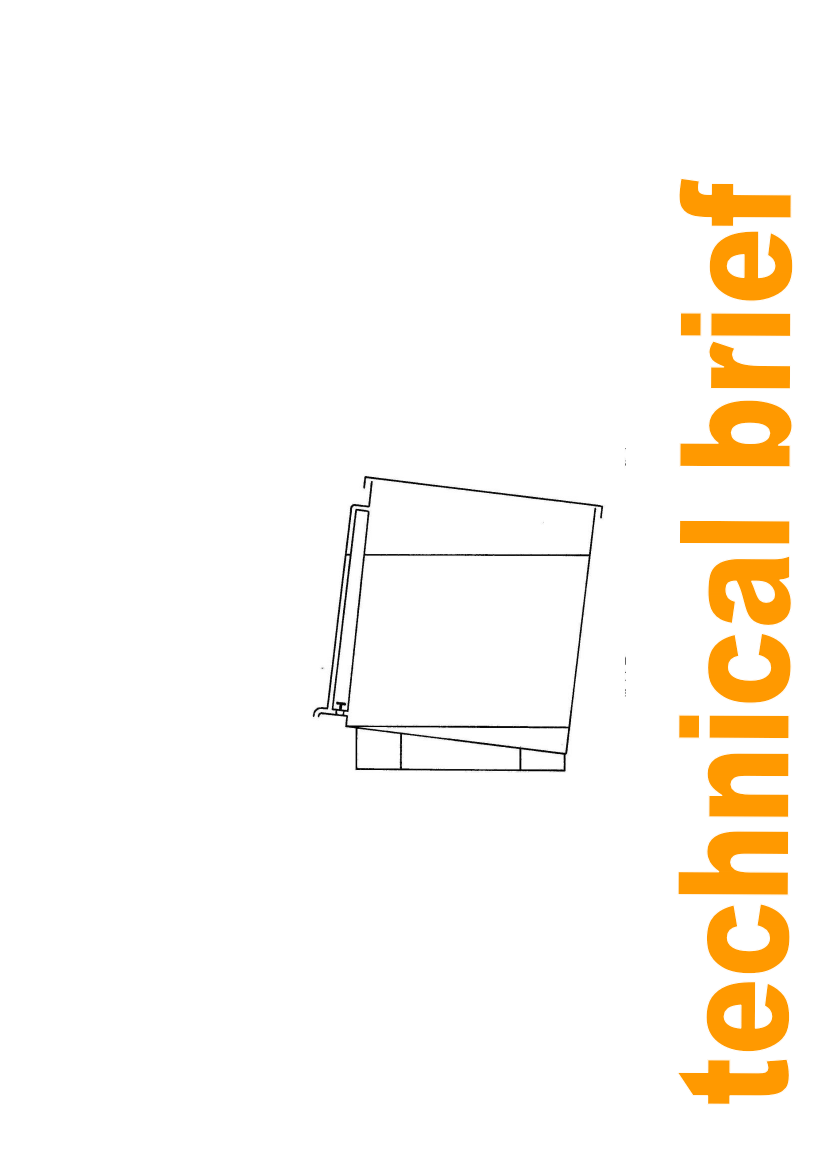

Next the racked juice is

clarified by the addition of a

small quantity; 2.5g/litres of

calcium carbonate (chalk

powder) which precipitates

the pectin cloud. After the

addition of calcium

carbonate, the juice should

be allowed to stand for 48

hours, to settle. The main

problem at this point is to

judge the boundary between

the clear juice and the

sediment. Inclining the tank

as shown in Figure 2 will

make separation of the clear

juice more efficient.

Sight

glass

Clear lime juice

Batch preparation and

pasteurisation

The batch is prepared by

Sediment

mixing together clarified lime

juice and a previously

prepared sugar syrup, the

whole being pasteurised by

heating to 80ºC for 5

Figure 2: Lime juice clarification using the tilted tank

method - Illustration: Practical Action

minutes. At the end of this

stage it will be found that the

original sulphur dioxide level will be reduced so as to conform with the generally acceptable

legal maximum of 350ppm. The subtle flavour of lime is sensitive to heat and it has been

found that the following system, which minimises the heating time, gives a very acceptable

product.

A 50º Brix sugar syrup is made by dissolving 6.15kg of granulated white sugar in 10 litres of

clean tap water. When fully dissolved, the syrup should be strained through several layers of

muslin as even refined sugar contains tiny black specks. The syrup is then raised to boiling

point in a convenient pan that can be made from aluminium.

2